-

NewsNews

-

Trade fairs

Trade fairs

-

Trade fairs

-

Textile filtrationTextile filtration

-

Filter cloth

-

Filter bags

Filter bags

-

Filter belts

Filter belts

-

More products

More products

-

Service

Service

-

Areas of application

Areas of application

-

White Paper

White Paper

-

Filter cloth

-

Hose technologyHose technology

-

HosesHoses

-

Couplings & connections

Couplings & connections

-

Accessories

Accessories

-

Service

Service

-

Areas of application

Areas of application

-

Knowledge Hub

Knowledge Hub

-

-

Other applications

Other applications

-

About usAbout us

-

Markert Group

Markert Group

-

Management & advisory board

Management & advisory board

-

Research and development

Research and development

-

Quality and the environment

Quality and the environment

-

Production system

Production system

-

Kunstforum Markert

Kunstforum Markert

-

Markert Group

-

CareersCareers

-

Training

Training

-

Jobs

Jobs

-

Work at Markert

Work at Markert

-

Training

-

Contact

Contact

1. Introduction

Steam is the gaseous phase of a substance that is typically liquid (or solid) at normal conditions. In a closed system, steam is in constant interaction with its original phase, meaning that at a constant temperature and pressure, a continuous transition of molecules between the liquid and gas phases occurs.

In many industrial processes, steam is indispensable – whether as a heat carrier or as a driving force in energy production.

Contact with steam can cause severe burns. Especially overheated steam can expand explosively when pressure drops, releasing large amounts of energy. When steam suddenly condenses, a vacuum is created, which can cause pipes to deform or even collapse.

The selection and maintenance of appropriate fittings are therefore crucial. Clearly, connection systems should be chosen that are specifically designed for use with steam.

Steam couplings for hose lines ensure the safe and efficient transport of steam. They provide a reliable connection in steam-powered systems, thereby improving operational safety and energy efficiency.

These couplings are specifically designed for use at high temperatures and pressures.

National and international standards define a safe benchmark. They are characterized by ease of use, without compromising on safety.

2. Types

Flanged connections:

Flanged connections are widely used and well-suited for steam applications. They provide a strong, durable, and reliable connection. For safe use, the flanges must be properly sized and matched to the specific operating conditions. They should only be used with suitable gaskets!

Threaded couplings:

Threaded couplings are widely used for steam applications and suitable for many uses. In particular, G-threads (ISO 228-1) and R-threads (EN 10226) are used for elastomeric steam hose lines. For other applications, especially at very high pressures or for the transport of superheated steam, other threaded connections or flanged connections should be preferred.

Clamp connections:

Clamp connections are only partially permissible for steam fittings, and their suitability and use must be carefully evaluated. They must be installed and secured in such a way that they cannot be unintentionally released under pressure. Clamp connections carry an increased risk, as when loosened, the entire pipe cross-section is exposed.

Coupling systems:

Coupling systems for steam should be specifically designed for use at high temperatures and pressures. They must be installed and secured in such a way that they cannot be unintentionally released under pressure. Many coupling systems carry an increased risk, as when loosened, the entire pipe cross-section is exposed.

In steam fittings, it is especially important that the entire pipe cross-section is not immediately exposed when unintentionally released, in order to avoid hazards such as steam leakage, steam jets, burns, or sudden pressure drops.

When selecting materials, high-temperature and high-pressure resistant materials, such as stainless steels or special alloys, should be preferred. Spark-sensitive materials should be avoided, especially in explosionhazardous areas.

Regardless of the type of connection, the fitting should be regularly inspected to ensure its functionality and long-term safety.

3. Standards and Regulations

Applicable standards and regulations for hose lines in steam applications are:

Pressure Equipment Directive 2014/68/EU

Regulates the requirements for pressure equipment and pipelines throughout the European Union

AD 2000 Data Sheet

Rules the design, safety-related requirements, and standards for pressure vessels and pipelines in Germany (and partially in other EU countries)

DIN EN ISO 6134

Rubber hoses and hose assemblies for saturated steam – Specification.

DIN EN 14423

Hose fittings with clamp connection for steam up to 18 bar.

ASME B31.1

This standard by the American Society of Mechanical Engineers (ASME) sets the requirements for the design, installation, and inspection of piping systems used in power plants, industrial heating systems, boiler rooms, and other steam and water piping. It is primarily used as a reference outside the United States.

4. The Markert Marsoflex Universal Coupling

The Markert Marsoflex Universal Quick Coupling offers optimal safety and speed – the connection can be easily and securely disconnected without additional tools, without immediately releasing the entire pipe cross-section.

Functionality

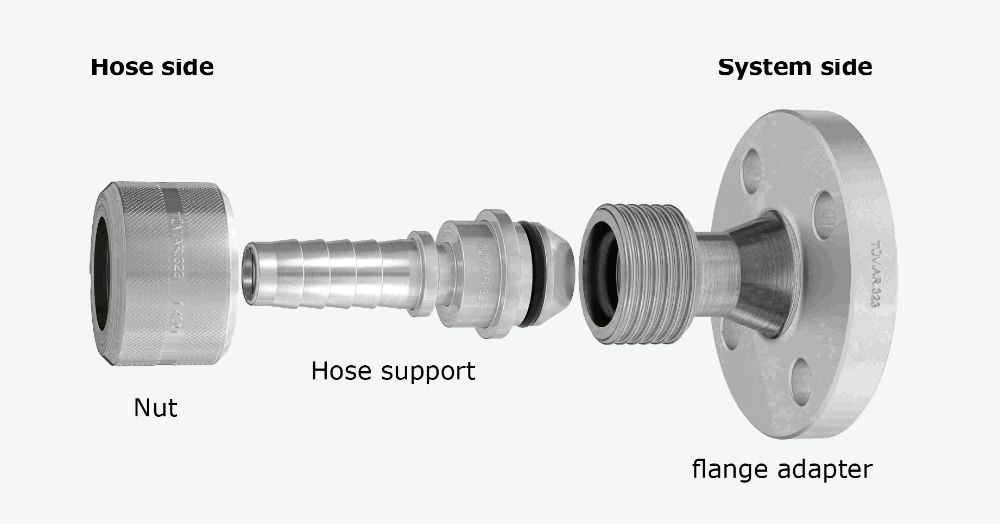

The Markert Marsoflex Universal Quick Coupling consists of a male and female part:

Description

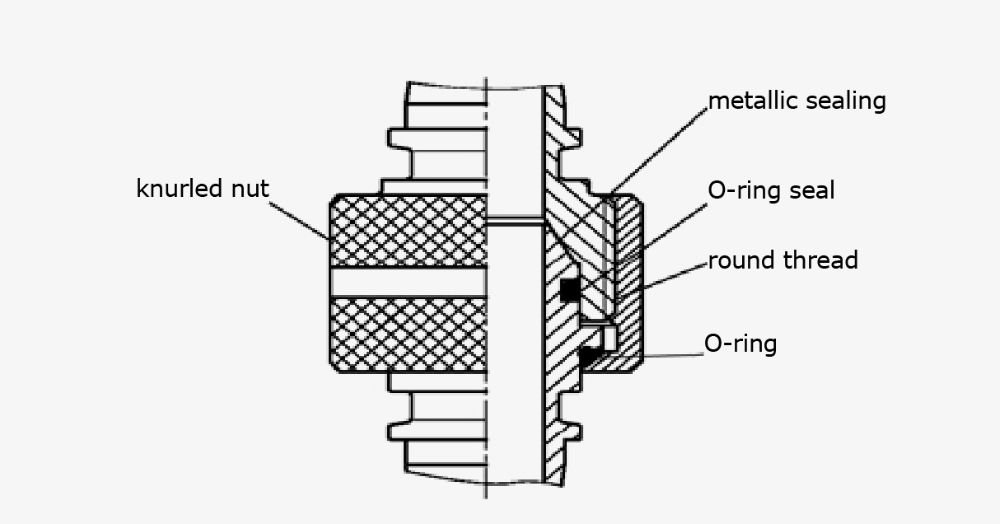

The male part is equipped with an internal cone, while the female part connects to a matching external cone and an additional O-ring seal. This coupling is secured using a knurled nut. A firm hand-tight connection is sufficient for safe operation, so tools are not required. This makes it ideal for quick and easy coupling and uncoupling of hoses.

If the hose line is still under pressure when disconnecting, any leakage can be detected with just a few degrees of rotation.

The threaded connection remains fully engaged and can be quickly re-tightened to ensure a secure seal without risk.

The system can then be safely relieved, and the connection can be safely disconnected afterward.

The coupling is standardly equipped with a flat thread, and a trapezoidal thread is also available. This makes it suitable for applications where connection compatibility must be excluded.

The advantages of this coupling summarized once again:

- Double-acting seal (metallic and O-ring)

- High level of safety for the user and long service life

- Easy and comfortable handling due to low coupling force

- Quick coupling without the need for tools

- Extremely robust, resistant, space-saving, compact design, easy to maintain and operate

- Suitable for steam up to 210°C and 18 bar, hot water up to 120°C and 18 bar, cold water and compressed air up to a working pressure of 40 bar

- Connections are standardly made from material 1.4404, and upon request, from 1.4571, 1.4301, or other materials

- Upon request, delivery with a certificate of conformity according to EN 10204-3.1 is possible