Food-grade hoses for the highest demands

Depending on the application, different hose materials are used:

In milk and meat processing, hoses made of natural rubber (NR) or nitrile rubber (NBR) have proven effective. For fermentative processes, hoses made of ethylene propylene diene rubber (EPDM) are ideally suited.

For applications involving fruit acids or high-proof alcohols, hoses with a liner made of UPE (ultra-high molecular weight polyethylene) offer the best chemical resistance and product safety.

Regardless of the application, the resistance of the hose material to cleaning and sterilization processes should always be considered to ensure hygiene and durability.

The material UPE – Robust, resistant, versatile

UPE (ultra-high molecular weight polyethylene) is characterized by a particularly high molecular weight, which positively influences its physical and mechanical properties. Compared to other types of polyethylene, UPE is extremely tough, impact-resistant, and has significantly higher abrasion resistance. These properties make it ideal for applications involving high mechanical stress or strong abrasion.

Additionally, UPE offers impressive chemical resistance to approximately 95% of all common chemicals. This combination makes UPE a universal and reliable liner material for hoses and hose assemblies in the food industry.

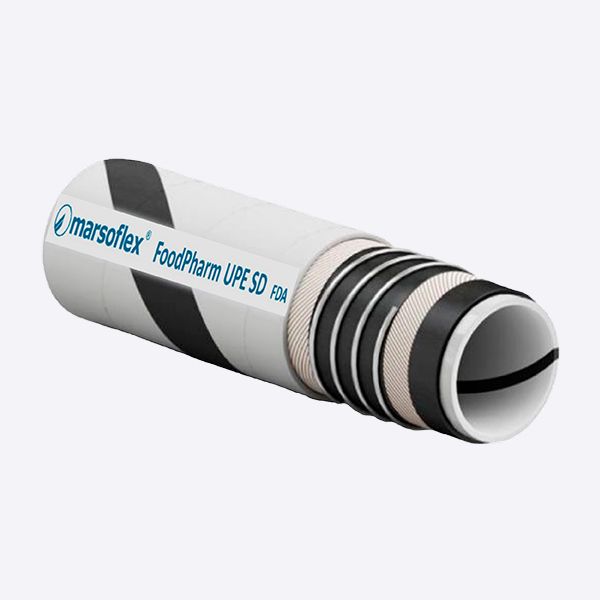

Features of the FoodPharm UPE hose

The FoodPharm UPE hose stands out for its high chemical resistance and is particularly suitable for transporting fruit acids or high-proof alcohols. Its robust, relatively hard UPE liner also ensures excellent abrasion resistance – ideal for applications with abrasive media.

In the food industry, many products such as beer, milk, or juices are water-based and naturally conductive, meaning electrostatic charging is usually not an issue.

However, when conveying powders, granules, or alcohol – such as dietary supplements, milk powder, or powder mixtures – electrostatics become a critical factor.

For use in ATEX-certified areas, not only the liner but also the hose cover must be conductive. The FoodPharm UPE is therefore equipped with seamlessly integrated conductive strips that ensure safe dissipation of static charge.

A universal food-grade hose with the highest standards

The FoodPharm UPE combines chemical resistance, abrasion resistance, and electrostatic safety in one product – while meeting all relevant compliance standards:

- UPE liner with high chemical and abrasion resistance

- Compliances: FDA, EC 1935/2004, EU 10/2011, GMP, and more

- Liner and cover made of white, food-grade materials

- Conductivity for ATEX areas thanks to integrated conductive strips

- Spiral construction for suction and pressure applications

PFAS-free thanks to UPE – safety for your production

The discussion around PFAS (per- and polyfluorinated alkyl substances) is currently gaining momentum. One major advantage of UPE: the material is naturally PFAS-free – without compromising performance or safety.

Markert Marsoflex food-grade hoses – Quality meets innovation

With Markert Marsoflex food-grade hoses, we offer a comprehensive product range for nearly all applications in the food industry – from fruit juices, dairy products, and beer to spirits and powders.

Our hoses stand for:

- Durability and sustainability

- Continuous quality control

- Maximum product safety and purity

Our experts are always available to support you in selecting the right hose for your specific application.